Discover How Speed Reducers Maximise Heavy Machinery Efficiency: Order from Global Bearings

November 26, 2024

Maximise heavy machinery efficiency with high-quality speed reducers from Global Bearings. Uncover how these bearings enhance performance and reduce wear.

When performing specific tasks in construction, mining, agriculture, and other industrial applications, operators often rely on heavy machinery. These large, powerful pieces of equipment are essential for tasks that require significant force or capacity, such as lifting, digging, grading, and transporting materials. These machines are built to handle demanding environments and are typically equipped with advanced technology to improve efficiency, safety, and precision in operations.

One thing that can be added to optimise their performance is speed reducers. Know more about these mechanical devices and their working principles.

What are Speed Reducers?

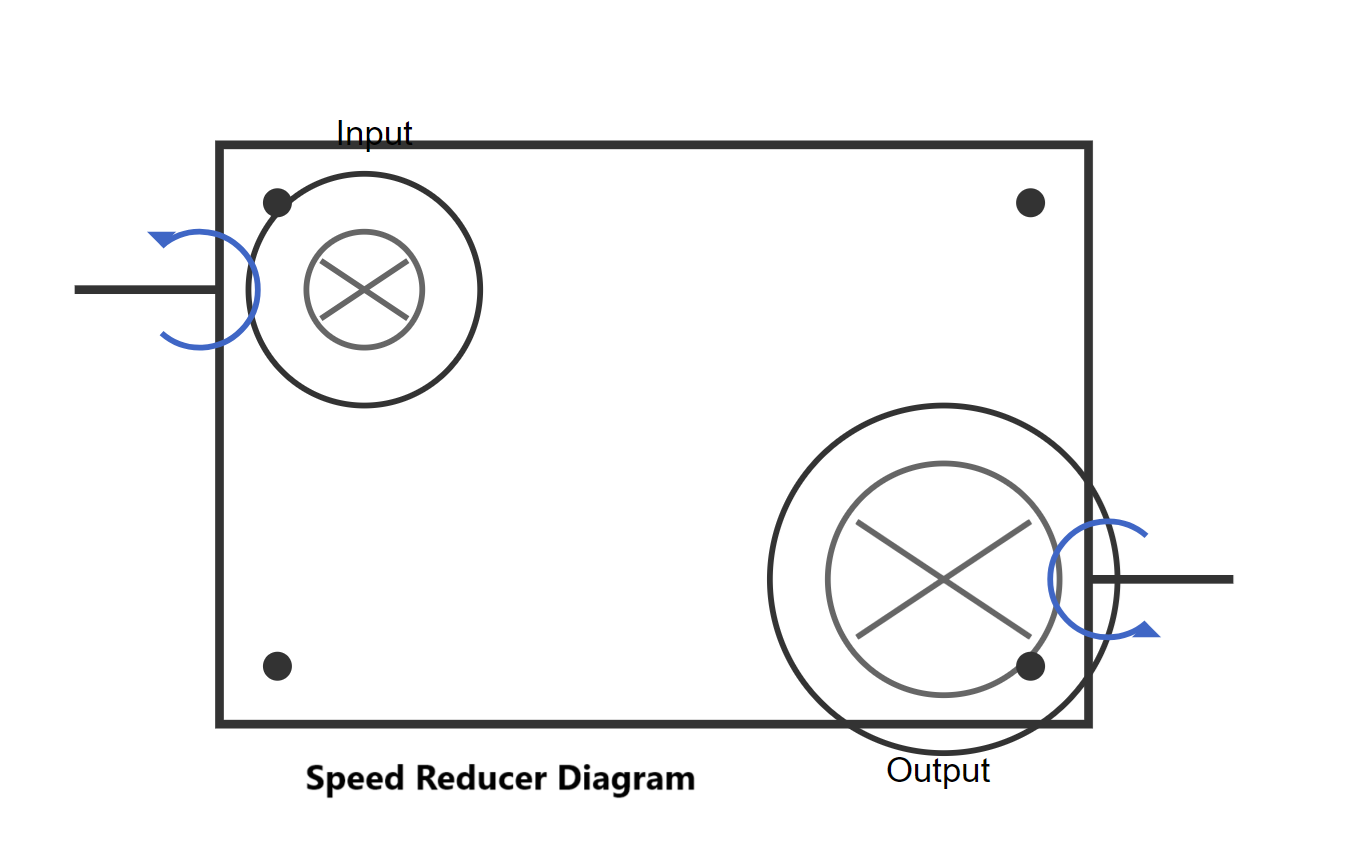

Speed reducers are mechanical devices designed to reduce the rotational speed of an input power source, such as an electric motor while increasing the torque output. They achieve this through a system of gears or belts, altering the speed ratio between the input and output shafts.

Speed reducers are crucial in applications requiring precise control of movement or heavy-duty operations. By reducing speed, they allow equipment to function at optimal speeds for specific tasks, ensuring efficiency, safety, and longevity.

How Do Speed Reducers Work?

Speed reducers operate on the principle of gear reduction, where the input shaft is connected to a series of gears. When the input shaft rotates, it drives a larger gear or the output gear, resulting in speed reduction.

It is typically achieved through various gear configurations like spur gears, bevel gears, or planetary gears, each offering different advantages in terms of size, efficiency, and torque output.

As the speed decreases, the torque output increases, allowing the machinery to handle heavier loads and operate more efficiently at the desired speed. The design of these mechanical devices then ensures that they provide optimal performance while minimising energy loss, making them essential components in many mechanical systems.

Where to Use Speed Reducers?

Various machines can benefit from speed reducers, including:

• Conveyor Systems: Speed reducers can be installed in conveyors, allowing them to move materials at controlled speeds, ensuring efficiency, and reducing wear on the system.

• Cranes and Hoists: Speed reducers can also provide cranes and hoists the necessary torque to lift heavy loads smoothly, enabling precise control during operations.

• Pumps: Speed reducers help pumps maintain optimal flow rates and reduce energy consumption by lowering motor speed while increasing torque.

• Industrial Mixers: Speed reducers provide industrial mixers with the consistent mixing speeds they need for various materials, improving product quality.

• Agricultural Equipment: Speed reducers enhance the performance of tractors and harvesters, which allows them to handle heavy loads effectively.

By adjusting speed and torque, these machines can operate efficiently, ensuring safety and longevity while reducing operational costs.

To ensure your machinery operates smoothly, you should source your speed reducers from a reliable supplier like Global Bearings. We offer durable and efficient speed reducers designed for specific applications, reducing the risk of equipment failure. We also provide warranties, technical support, and after-sales services, which can be invaluable for maintenance and troubleshooting.

Additionally, our professional team can help you select the right speed reducer based on your machinery’s requirements, ensuring optimal performance and longevity.

Optimized by: Netwizard SEO