How Self-Aligning Bearings Compensate for Misalignment in Drive Assemblies

January 20, 2026

Global Bearings offers self-aligning bearings in Australia, ensuring the elimination of angular misalignment and improving efficiency in heavy-duty drives.

High-performance industrial machinery relies on the precise alignment of rotational components. Even marginal errors in mounting or operation lead to premature wear and system failure. Selecting the correct solution is essential, and this is where self-aligning bearings offer a reliable, purpose-built advantage in drive assemblies.

Causes of Positional Error in Machinery Operation

Misalignment is an inherent challenge across mechanical drive systems. The static setup or dynamic operation of equipment often introduces unexpected deviations in shaft positioning.

Common factors contributing to misalignment include:

• Inaccurate machining tolerances during component manufacture

• Improper installation practices and mounting procedures

• Foundation settling or shifting over time

• Thermal expansion and contraction during operational cycles

• Shaft deflection caused by heavy static or dynamic loads

The Design Advantage of Self-Aligning Bearings

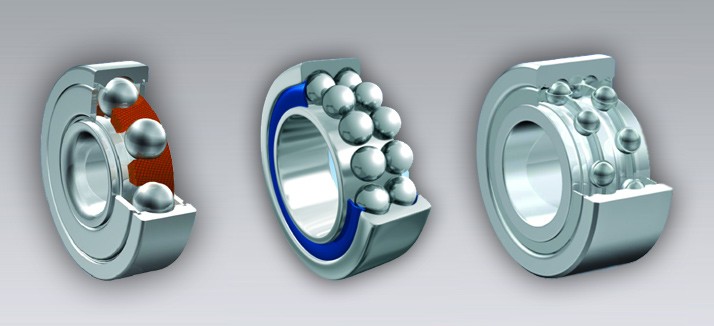

Precision components often experience initial mounting errors. These deviations place immense stress on traditional rigid bearings, concentrating loads unevenly across the rolling elements. The double-row design of these specialised bearings features a spherical outer ring raceway, which mechanically compensates for these angular inconsistencies.

The unique geometry permits the inner ring, cage, and rolling elements to swivel freely within the housing. The resulting action ensures the load is always distributed uniformly, maintaining full bearing capacity despite shaft misalignment. This capability drastically improves operational efficiency and extends the overall service life of the machinery.

Optimising Load Distribution and Performance

Mechanical drive systems require bearings capable of withstanding dynamic operational stress. Understanding how these specialised components manage extreme conditions highlights their integral value. The functional benefits of employing these bearings are numerous:

• Vibration Reduction: The bearing’s internal geometry allows it to accommodate shaft movement, reducing vibration transmission back into the machine structure.

• Extended Lubrication Life: Proper load distribution prevents localised heating, ensuring the grease or oil film remains intact and effective for longer operational periods.

• Reduced Seal Wear: By allowing the shaft to run centrally relative to the housing, the risk of seal damage caused by orbital motion is significantly diminished.

• High Radial Load Capacity: Despite their flexibility, self-aligning bearings maintain a robust design, allowing them to support substantial radial forces encountered in demanding industrial applications.

• Accommodation of Expansion: They effectively manage shaft elongation or contraction due to temperature fluctuations, preventing detrimental internal stresses within the component.

For a detailed examination of how positional errors compromise component lifespan, review the article ” On the Characteristics of Misaligned Journal Bearings.

Ensuring Drive System Reliability

System stability relies on proactively mitigating mechanical failure points. Specifying the correct self-aligning bearings eliminates the common risks associated with angular misalignment and shaft deflection. This strategic component choice guarantees maximum productivity and predictable maintenance cycles.

Global Bearings Australia supplies a comprehensive range of these essential industrial components, designed for the rigorous demands of Australian applications. We provide expert advice to select solutions that ensure superior performance and longevity for all your drive assemblies.

For tailored advice on optimising your machinery, contact us.

Related Blog Article: 5 Reasons Double Row Self-Aligning Ball Bearings Outperform Single-Row Bearings for Shaft Support

Optimized by: Netwizard SEO