Shafting Supply Essentials: Key Considerations for Custom Projects

January 9, 2025

Get top-quality shafting supply for custom projects in Australia. Global Bearing Imports ensures precise custom solutions tailored to your industrial needs.

When tackling custom projects, selecting the right shafting supply is crucial to achieving optimal performance and durability. At Global Bearing Imports, we specialise in providing high-quality shafting solutions across Australia, tailored to meet the specific demands of various industries. This guide highlights key considerations to ensure your custom shafting project runs seamlessly.

A Quick Overview of Shafting

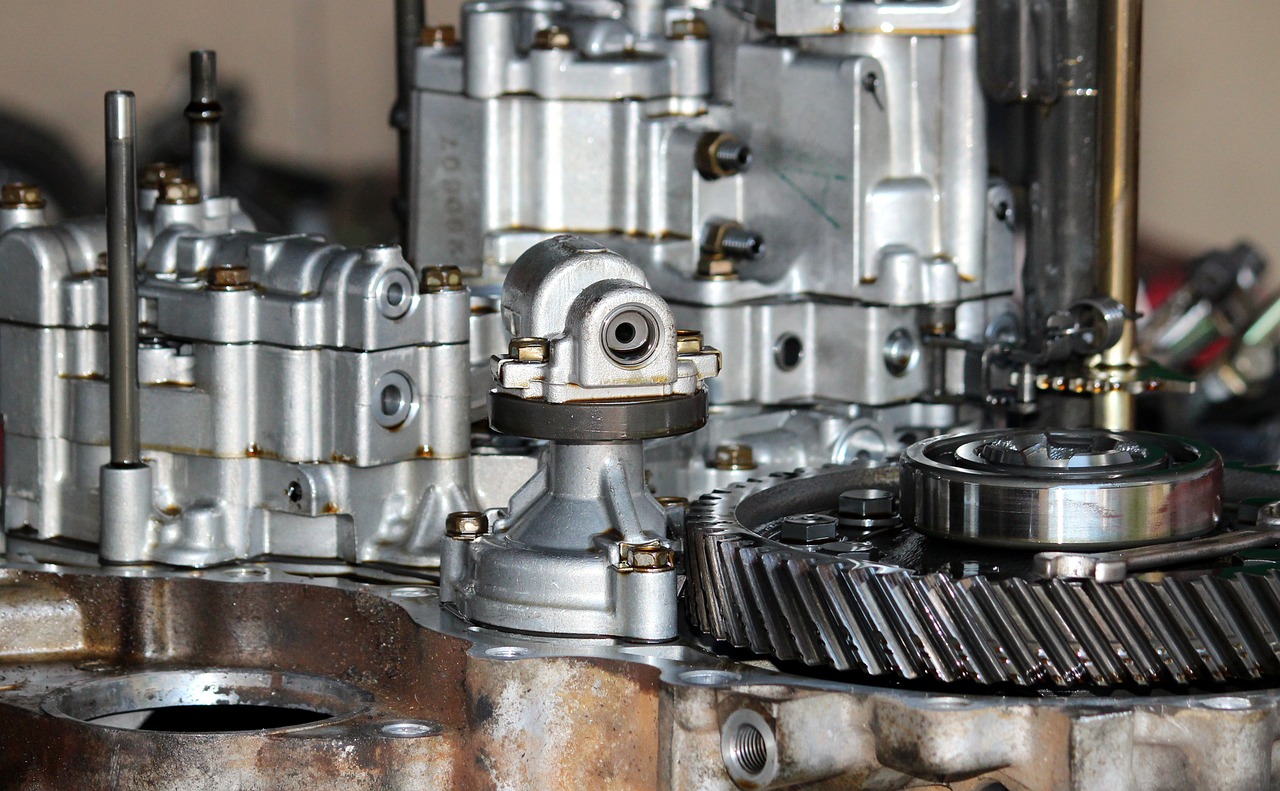

In mechanical systems, shafting refers to cylindrical components used to transmit power, torque, and rotational motion between different parts of a machine or system. Shafts are critical elements in a wide range of applications, from industrial machinery and automotive drivetrains to aerospace systems and marine equipment.

Some notable functions of shafts are as follows:

• Power Transmission: Shafts transfer mechanical power generated by motors or engines to other components like gears, pulleys, or wheels.

• Torque Handling: They transmit torque, ensuring that the rotational force drives the connected parts effectively.

• Rotational Alignment: Shafts maintain alignment between connected components, ensuring smooth and efficient operation.

Sourcing Your Shafting Supply

For custom projects, selecting the right shafting components is essential to ensure efficiency, durability, and performance. Whether you’re designing industrial machinery, automotive systems, or specialised equipment, understanding the essentials of shafting supply can make a significant difference.

Here are the key considerations to keep in mind when sourcing shafting for custom projects.

• Material: The material of the shaft is crucial to its performance and longevity. Different projects demand specific material properties, such as strength, corrosion resistance, or weight. Common shafting materials include carbon steel, stainless steel, aluminium, and alloy steel. The material you choose should align with your project’s operational conditions, such as load, temperature, and environmental exposure.

• Dimensional Accuracy: Custom projects often require precise shaft dimensions to ensure compatibility and optimal performance. Key factors to consider include diameter and length, tolerances, and straightness.

• Surface Finish: The surface finish of a shaft affects its performance in areas such as friction, wear, and fatigue resistance. A smoother surface reduces the risk of premature wear and enhances the shaft’s lifespan.

• Load Capacity and Stress Resistance: Understanding the load and stress requirements is vital when designing custom shafting. Consider factors like static loads, dynamic loads, and torsional stress. Choose a shaft material and design that can withstand these stresses without deforming or failing.

• Keyway and Mounting Features: Keyways, splines, or other mounting features allow the shaft to connect securely with other components, such as gears or pulleys. For custom projects, these features must align precisely with the system’s design to ensure seamless integration and performance.

• Machinability and Customisation: Custom projects often require shafting to be machined to specific shapes or sizes. High machinability ensures efficient production without compromising the shaft’s structural integrity.

Shafting is a foundational element of many mechanical systems, and its selection should never be an afterthought. By focusing on material properties, precision, and application-specific requirements, you can ensure that your custom project performs optimally.

Want to get the best supply of shafts for your machines? Contact Global Bearing Imports today! We specialise in supplying high-quality, custom shafting solutions for projects across Australia.

Optimized by: Netwizard SEO