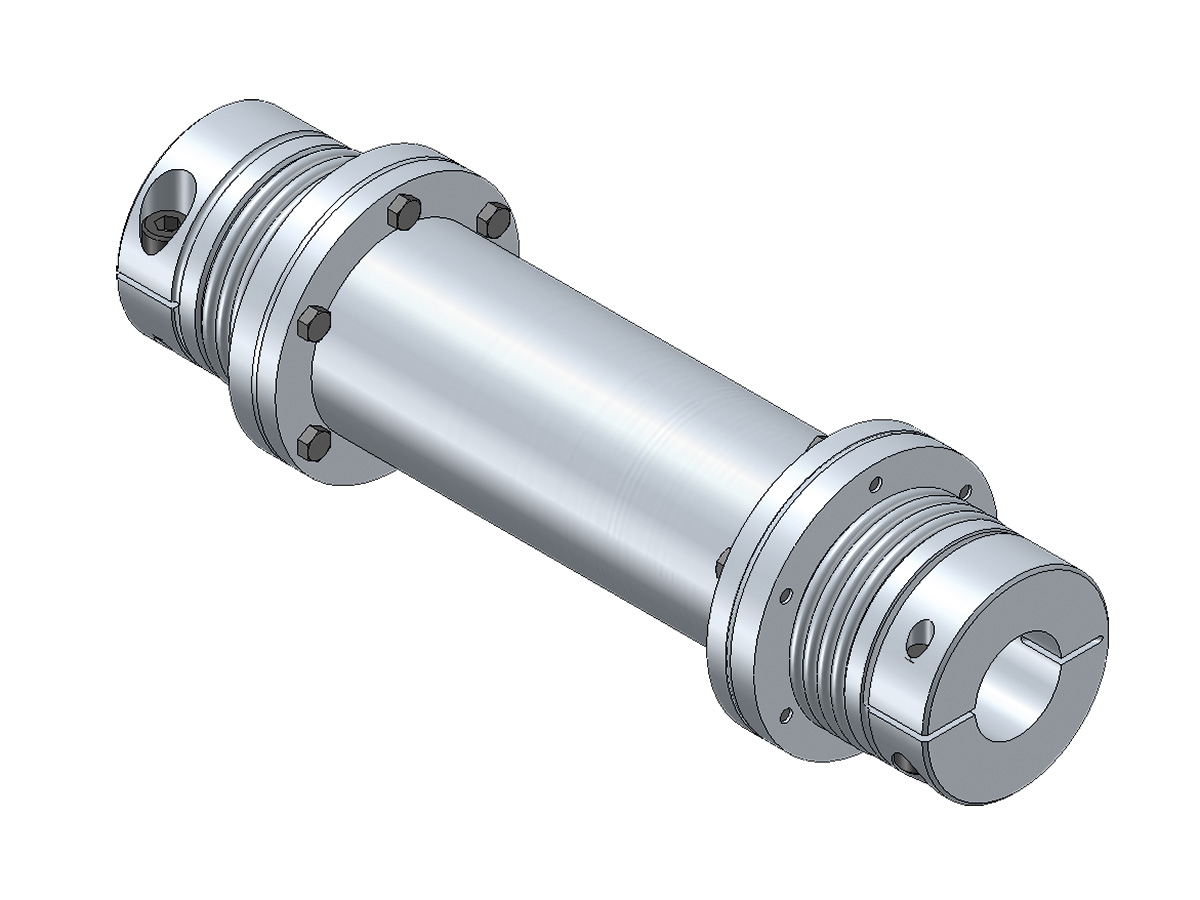

StS Intermediate Shaft Couplings for Smooth Power Transmissions

September 19, 2023Original Photo Image from: https://www.stscoupling.de/en/intermediate-shaft-coupling/

Global Bearings: Supplier of StS Intermediate Shaft Couplings – Smooth power transmission solutions. Trust us for reliable performance. Call (613) 9879 1199.

StS intermediate shaft couplings are highly reliable and efficient components utilised in various industrial applications for power transmission between driving and driven shafts. Manufactured by StS Coupling GmbH, they help ensure smooth power transfer, minimise power loss, and prevent misalignment or damage to the transmission system.

Smooth and efficient power transmission is vital in a wide range of industrial applications. Hence, industries would rely on intermediate shaft couplings to effectively connect shafts in a power transmission system. These mechanical devices not only transmit power from the driving shaft to the driven shaft, but they can also accommodate any misalignments due to thermal expansion, vibrations, or minor positioning errors during installation.

The intermediate shaft couplings of StS Coupling GmbH offer several benefits that make them useful for many applications. Knowing them can help industrial plant owners like you carry out their operations without any issues.

Benefits of StS Intermediate Shaft Couplings

StS intermediate shaft couplings play a pivotal role in achieving smooth power transmission, which helps optimise performance and efficiency in industrial settings. They can do this by minimising power losses, reducing vibrations, and preventing misalignment between shafts. They can also maximise system efficiency and minimise wear and tear on components by ensuring the smooth transfer of torque and rotational energy.

To make them more useful, they maximise the following features.

• High Torque Capacity: StS intermediate shaft couplings can easily handle high torque loads, making them suitable for demanding industrial applications.

• Flexibility and Misalignment Tolerance: The intermediate shaft couplings can also accommodate angular, axial, and parallel misalignments, which allows for smooth operation even in challenging conditions or settings.

• Damping Properties: StS intermediate shaft couplings possess inherent damping characteristics that make them effective in dampening vibrations and reducing stress on connected equipment in a variety of industrial settings.

• Maintenance-Free Operation: The robust construction of StS intermediate shaft couplings ensures long-lasting performance with minimal maintenance requirements, which leads to reduced downtime and enhanced productivity.

StS Intermediate Shaft Couplings Applications

StS intermediate shaft couplings find application across various industries, including power generation, marine, and industrial machinery. They are used in turbine drivetrains, generators, and other critical equipment in power generation. In the marine sector, StS intermediate shaft couplings ensure reliable power transmission in propulsion systems, thrusters, and auxiliary machinery. Industrial types of machinery like pumps, compressors, and conveyors can also benefit from the smooth and efficient operation provided by StS intermediate shaft couplings.

But to make them effective in these applications, one should select an appropriate coupling. Some factors to consider in choosing the best coupling include torque requirements, operating conditions, misalignment tolerances, and environmental factors. Once the right coupling has been selected, proper installation must be done. The manufacturer’s instructions should be followed during installation, which may cover proper alignment and torque specifications. The installed couplings must then be inspected, lubricated, and maintained regularly to ensure their continued smooth operation.

StS intermediate shaft couplings provide reliable and efficient power transmission in various industrial applications. Their high torque capacity, flexibility, and damping properties can provide enhanced performance, reduced downtime, and extended equipment lifespan.

Optimized by: Netwizard SEO