StS Magnetic Couplings for Unique Engineering Challenges

October 17, 2023

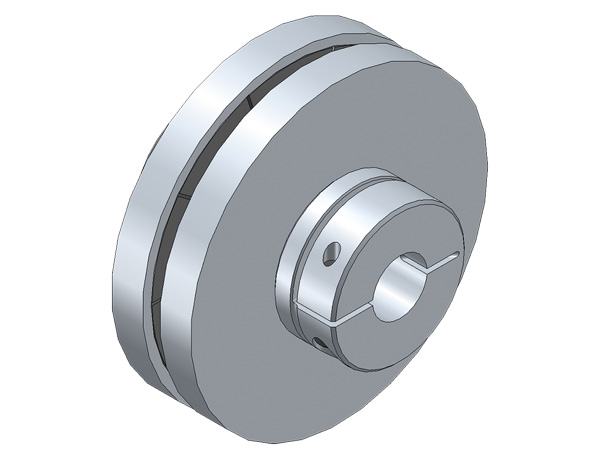

Original Photo Image from: https://www.stscoupling.de/en/magnetic-coupling/ks/

Overcome engineering challenges with StS magnetic couplings. Available at Global Bearings, know how they work, their benefits, and uses. Call (613) 9879 1199.

Innovation often stems from the need to overcome unique challenges and push the boundaries of possibilities. In the realm of engineering, one such innovation that has garnered attention in recent years is the StS magnetic coupling. Designed to address specific engineering complexities, these magnetic couplings offer a wide range of benefits and applications across various industries. With these things, solving intricate engineering problems can be a breeze.

Magnetic Couplings: Working Principles

Magnetic couplings, including those developed by StS, serve as a mechanical link between two rotating shafts without any physical contact. They maximise the power of magnetic attraction and repulsion to transmit torque, allowing for efficient power transmission even in challenging environments. This working principle eliminates the need for traditional shaft seals and offers an array of advantages, which makes it particularly well-suited for applications where leak prevention, maintenance reduction, and high torque transfer are critical.

Advantages of StS Magnetic Couplings

StS Coupling GmbH is a known manufacturer of a variety of couplings, making them a reliable partner for drive technology. As they prioritise the satisfaction of their customers, the company continues to innovate their coupling offerings, which include magnetic couplings.

Numerous benefits can be expected out of StS magnetic couplings.

• Eliminated Leaks: The seal-less design of StS magnetic couplings eliminates the risk of fluid leakage, making them ideal for applications involving hazardous or sensitive fluids.

• Improved Efficiency: StS magnetic couplings offer efficient torque transmission, resulting in less energy loss and optimised system performance.

• Reduced Maintenance: Without physical contact between the shafts, there is minimal wear and tear, leading to reduced maintenance requirements and extended equipment lifespan.

• Optimised Design: The compact nature of StS magnetic couplings allows for easy integration into existing systems without significant modifications.

• Granted Customisation: StS magnetic couplings can be tailored to suit specific application requirements, which ensures optimal performance and functionality.

Applications of StS Magnetic Couplings

One of the remarkable aspects of StS magnetic couplings is their versatility in addressing diverse engineering challenges. They find applications in several industries.

The chemical and process industries, for one, use these couplings to prevent leakage of hazardous or corrosive fluids, maintaining the integrity of the process and ensuring the safety of workers. Pharmaceuticals and food production likewise use these couplings to prevent fluid contamination and preserve product purity, allowing them to adhere to strict hygiene and contamination control requirements.

Power generation is another industry that can maximise StS magnetic couplings. They use these couplings in power plants for efficient torque transmission between turbines and generators, contributing to stable and reliable power generation. Automotive and manufacturing then use these couplings to facilitate the transmission of torque in manufacturing equipment, ensuring precision and reducing maintenance needs. Ultimately, StS magnetic couplings can be utilised by the water treatment industry as an innovative solution for its processes, eliminating the risk of fluid leakage and enhancing system reliability.

StS magnetic couplings, which can be purchased at Global Bearings, represent a groundbreaking solution for addressing unique engineering challenges across a spectrum of industries. Their ability to provide leak-free, efficient torque transmission in various environments underscores their value in enhancing system reliability, safety, and performance. As industries continue to encounter increasingly intricate engineering hurdles, innovative technologies like these are poised to overcome challenges and drive progress forward.

Optimized by: Netwizard SEO