NILOS Seal Selection Guide: Pick the Right Seal for Your Critical Application

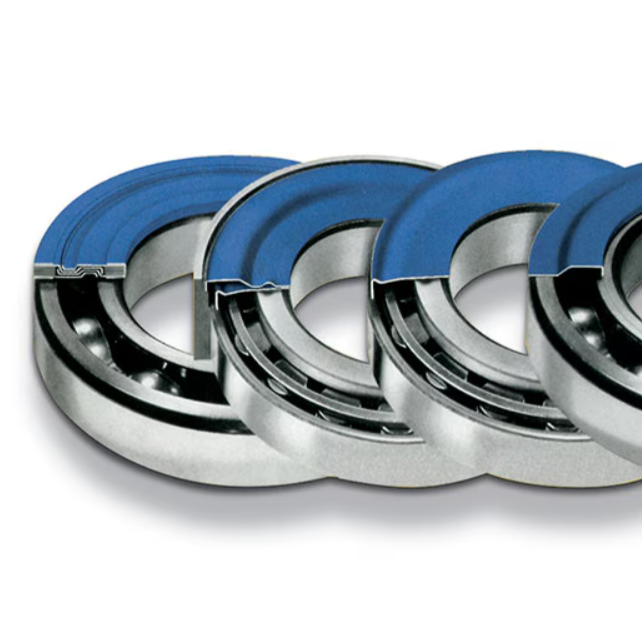

May 8, 2024 Original Photo Image from: https://www.skf.com/us/products/other-products/nilos-rings

Original Photo Image from: https://www.skf.com/us/products/other-products/nilos-rings

Navigate the NILOS seal selection guide to choose the perfect seal for your critical application. Available at Global Bearing Imports, invest in one today.

Choosing the right NILOS seal for critical applications can be a daunting task, with numerous factors to consider, including operating conditions, material compatibility, and sealing performance.

To simplify this process, Global Bearing Imports offers a comprehensive NILOS seal selection guide designed to assist businesses in selecting the most suitable seal for their specific requirements. Get to know the key features of NILOS seals and attain insights and tips for picking the right seal for your applications.

An Overview of NILOS Seals

NILOS seals are renowned for their high-quality construction, innovative design, and superior sealing performance. Available in a wide range of materials, including rubber, silicone, and polyurethane, NILOS seals are designed to meet the diverse needs of various industries, from automotive and aerospace to manufacturing and mining.

NILOS seals offer numerous benefits that make them vital in these industries. They offer exceptional chemical resistance, temperature tolerance, and durability, ensuring long-term reliability even in the harshest operating conditions. Their precision engineering and advanced sealing technology result in minimal leakage rates, reduced wear, and extended service life, contributing to improved equipment uptime and operational efficiency.

Additionally, NILOS seals are easy to install and maintain, facilitating hassle-free integration into existing systems and reducing maintenance costs over time.

Selecting Your NILOS Seals

Picking the right NILOS seal for your application involves several key steps to ensure optimal performance and reliability.

• Understand Application Requirements: Begin by clearly defining the operating conditions, fluid compatibility, and performance expectations for your application. You must consider factors such as temperature, pressure, speed, and exposure to chemicals or contaminants.

• Consider Material Compatibility: NILOS seals are available in a wide range of materials, each tailored to different operating conditions and fluid compatibility. You should evaluate the compatibility of seal materials with the fluids, chemicals, and environmental conditions present in your application to ensure long-term reliability and performance.

• Assess Seal Performance: Evaluating the performance data provided for each seal option, including leakage rates, wear resistance, and service life expectancy, is necessary. You must compare different seal options based on their performance characteristics to identify and choose the best fit for your application requirements.

• Think Long-Term Reliability: Look beyond the initial cost and consider the long-term reliability and maintenance requirements of the selected seal. You should choose seals that offer durability, reliability, and minimal maintenance to minimise downtime and maximise equipment uptime.

• Perform Regular Maintenance: Even the best seals require regular inspection and maintenance to ensure optimal performance. You must, therefore, implement a proactive maintenance schedule to monitor seal condition, address any issues promptly, and extend the lifespan of your NILOS seals.

With NILOS seals, reliability, durability, and performance are assured, providing peace of mind and enhancing operational efficiency in diverse industrial environments. If you are unsure about which seal to choose, do not hesitate to consult with Global Bearing Imports. We can provide valuable insights and navigate through various seal options to help you pick the right one for your industrial applications.

Optimized by: Netwizard SEO